Cruising sailboats are compromises in every sense. The boat that functions best tied to a dock often is the worst boat to take offshore. The great offshore boat often has features undesirable for lounging at anchor. But that's life. Compromise is essential.

Appearance, cost, safety, performance, accommodation, ease of handling, resale value, maintenance and longevity are all very important factors to take into account when designing a boat. Successfully blending these conflicting requirements is the crux of yacht design. There is no magic formula, nor can a computer do it. First hand experience is crucial. Extensive cruising, racing and boat building experience are required background for quality yacht design.

It is also very important for the designer to acknowledge from the outset of the design process that he does not know everything, nor can he possibly envision all the combinations of circumstances that could cause damage to the boat or injury to the crew. Many yacht designers wax poetic about their ability to calculate and predict every aspect of the performance their designs, thus claiming that they can create the “optimum” design. Unfortunately, the real world often treats “optimum” designs very harshly. When the unforeseen happens (and it will) the “optimum” design often fails catastrophically. At the very least, structural failures are usually expensive to fix- possibly extremely expensive if the boat is far away from the required facilities. But worse is the potential for personal injury as well as complete disruption of a long cruise. In some cases minor structural failures compound themselves to create even larger problems, causing the complete loss of the vessel.

Therefore, I have always considered it crucial that the essential structure and systems of a cruising boat, which by definition will sail far from home and be exposed to an enormous variety of conditions, be executed not only with a decent factor of safety but also with certain areas intentionally overbuilt to prevent failures in one area from progressing to another. This does not mean that the entire vessel should be overbuilt or unnecessarily heavy. Multihulls need to be strong and light in order to work well. But certain critical structural areas need to be amply strong to deal not only with the expected loads but also for the unexpected, unforeseen and unknown. I always design my boats with this in mind.

I built my first trimaran in 1973 and have been involved with multihull sailing, design and construction ever since. My yacht design business began in 1983 after I returned from a 2 year cruise on a 52' trimaran (Juniper) that I designed and built. I believe that cats and tris offer the cruising sailor the best combination of features for long distance cruising and am dedicated to developing the most advanced designs for fast, safe and comfortable cruising boats.

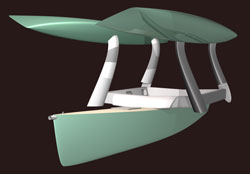

My design drawings are accomplished with computer aid. Hulls, decks and crossbeams are modeled in 3D. Construction drawings are CAD based and carefully prepared; all the parts of the boat fit accurately together. This level of construction drawing takes a great deal of time to prepare but results in time saved in construction, and in higher quality throughout

My design drawings are accomplished with computer aid. Hulls, decks and crossbeams are modeled in 3D. Construction drawings are CAD based and carefully prepared; all the parts of the boat fit accurately together. This level of construction drawing takes a great deal of time to prepare but results in time saved in construction, and in higher quality throughout

Chris White designs are built professionally by a number of quality boatyards around the world but occasionally are constructed by qualified amateur builders. In every case I remain in close contact with the builder throughout the process.

Whether you are looking for a stock or custom design, or even a second hand catamaran or trimaran, please call with your requirements.

-A note for amateur builders:

It is difficult for owner/builders who have never built a boat before to realize how much work and money is involved building a quality boat. Most of the inquiries I receive from individuals who want to construct their own boat indicate that they significantly underestimate the project size and cost. Often they are off by a factor of 2 or 3. While there are efficient, workaholic owner/builders who get a good boat built in 3 or 4 years, they are rare. Others either never start, never finish, or take 10 years to finish. Having built two boats myself for my own use I understand the desire but I also know the pain involved. Unfortunately, there are no real shortcuts in construction methods. There are yacht designers who promise fantastic results in half the time due to some hull construction method they have devised. That might be true for part of the project but invariably the labor gains made in one area contribute to labor losses in the remainder of the construction. To complete a quality 45' cruising cat as a one-off project typically requires professionals approximately 15,000 construction man hours. For one person working 40 hours a week, 50 weeks a year, that's translates to 7 years construction time. The hulls are the quick and easy part. Like framing a house, in a matter of weeks it appears and the uninitiated get a big shot of adrenalin thinking they are home free. There is still SO much more to do. Smaller, simpler boats get built faster of course but the point I want to stress is that good boats are very expensive for a reason. Make sure you have the stamina and financial resources to complete any project you start because a partially built boat is worth very little.